If you’re a passionate hunter or shooting enthusiast, you already know how quickly ammunition costs can add up. Buying large amounts of ammo can be expensive, but there’s a smarter, more affordable solution—using a progressive reloading press. This powerful tool not only saves money but also helps you reload efficiently, making it a cost-effective and time-saving choice for shooters.

In this article, we’ll cover everything you need to know about the best progressive reloading press, including its features, types, and benefits. Stick with us until the end to discover which option might be the perfect fit for your reloading needs.

What Is a Progressive Reloading Press?

A progressive reloading press is a machine designed to help you reload used ammunition. It replaces the primer, adds fresh gunpowder, and resets the shell casing—producing reliable, ready-to-use rounds with ease.

Types of Progressive Reloading Press

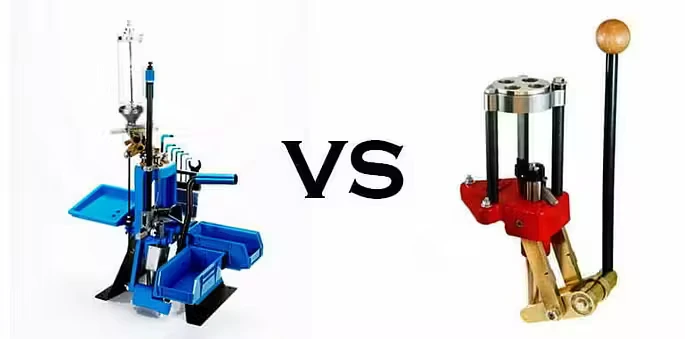

The main advantage of progressive reloading presses is that they come in two styles: auto-indexing and manual indexing.

- Auto-indexing press: Each pull of the handle automatically advances the shell to the next stage. This speeds up the process and reduces the risk of double charging, though it doesn’t completely eliminate errors.

- Manual-indexing press: With these models, you manually rotate the shell plate after each pull. While slower, many shooters find them more reliable and flexible for complex tasks.

👉 Related Posts:

Best Progressive Reloading Press

| Model | Type | Capacity | Key Features | Best For |

|---|---|---|---|---|

| Hornady Lock-N-Load AP Press | Auto-Indexing | Up to 500 rounds/hr | EZject system, Quick die change, Case feeder | High-speed, precision reloading |

| Lee Precision Load Master 45 Kit | Auto-Indexing | Up to 400 rounds/hr | Quick caliber change, Strong ram | Affordable and beginner-friendly |

| Dillon Precision RL550C | Manual Indexing | High output | Primer alert, Accurate powder drop | Experienced reloaders |

| Lee Load Master 223 Kit | Auto-Indexing | Up to 500 rounds/session | Dual-mode, Quick turret change | Best value option |

| Lee Precision 90940 Load Master | Auto-Indexing | Up to 400 rounds | Primer feeder, Easy setup | New reloaders on a budget |

1. Hornady Lock-N-Load AP Press Loader

Specifications:

| Dimensions | 20 x 14 x 11 inches |

| Weight | 29 Pounds |

| Brand Name | Hornady |

| Warranty | Lifetime Warranty |

| Material | Cast Iron |

To reload ammunition quickly and efficiently, Hornady introduced the Lock-N-Load AP Press Loader — a reliable, high-performance choice for shooters who demand speed, accuracy, and precision.

Key Features

- Five-Station Progressive Press: Designed for simplicity and versatility, this press can handle multiple calibers and uses an auto-indexing system to maximize productivity.

- EZject System: Ensures smooth and reliable ejection of each cartridge, maintaining a consistent high output during reloading.

- Universal Case Retention Spring: Keeps each case securely in place, even when you need to remove one between stages.

- Quick Die Change Technology: The Lock-N-Load bushing system allows fast, hassle-free die changes when switching calibers.

- Case Feeder & Priming System: Streamlines the entire process, helping you reload more rounds in less time.

Whether you’re a hobbyist or an experienced shooter, the Hornady Lock-N-Load AP Press Loader is an excellent investment that delivers speed, precision, and convenience for all your reloading needs.

Pros & Cons

| Pros | Cons |

|---|---|

| Five-station progressive design | Higher price compared to competitors |

| Easy to set up and simple to use | Requires purchasing extra accessories |

| Accurate powder measurement | Lock-N-Load bushing may occasionally get unseated |

| Fast and efficient reloading process | — |

Why You’ll Love It

The Hornady Lock-N-Load AP Press Loader offers professional-grade performance and is built to handle serious reloading demands. Its combination of speed, accuracy, and ease of use makes it a favorite among shooters who value quality and efficiency.

If you’re serious about reloading and want a durable, high-output progressive press, the Hornady Lock-N-Load AP is worth every penny. It saves time, improves accuracy, and delivers consistent results with every pull.

2. Lee Precision Load Master 45 Reloading Pistol Kit

Specifications:

| Feature | Details |

|---|---|

| Dimensions | 19 x 11 x 10 inches |

| Weight | 1 Kilogram |

| Brand Name | Lee Precision |

| Country of Origin | United States |

| Included | Progressive Press Kit |

Why Choose Lee Precision Load-Master?

If you’re looking to upgrade from a single-stage or turret press to a progressive reloading press, the Lee Precision Load-Master is one of the best and most affordable options. It’s lightweight, durable, and designed for high-speed, reliable ammo production.

- Lightweight & Strong: Built with a cast aluminum structure, it’s easy to handle without losing durability.

- Quick Caliber Changes: Connected dies and a quick-change tool head let you switch calibers effortlessly.

- High Productivity: With five reloading stations, it can produce up to 400 rounds per hour, ensuring speed and consistency.

- Handles Heavy Loads: The enlarged chrome-plated ram diameter supports heavier rifle cartridges, including magnum loads.

- Clean & Safe Operation: The Pro-Auto Disc Powder Measure minimizes gunpowder leakage.

Pros & Cons

Pros:

- Five efficient stations

- Fast reloading speed

- Easy to set up and use

- Solid build quality

Cons:

- Requires some additional accessories

The Lee Precision Load-Master Progressive Reloading Press is a smart investment for shooters who want speed, flexibility, and affordability. Whether you’re reloading standard ammo or heavy rifle cartridges, this press delivers consistent performance and saves you valuable time.

3. Dillon Precision 14261 RL550C 4 Stage Manually Indexed Progressive Reloading Machine

If you’re looking for a high-quality, heavy-duty progressive reloading press, the Dillon Precision 14261 RL550C is a top contender. Known for its precision, productivity, and durability, this model is ideal for reloaders who value performance and reliability.

Key Specifications

| Feature | Details |

|---|---|

| Package Dimensions | 28 x 13 x 5 inches |

| Package Weight | 26 pounds |

| Brand | Dillon Precision |

| Manufacturer | Dillon Precision Products, Inc. |

| Size / Caliber | 9mm |

| Stations | 4 |

| Type | Manual-Index Progressive Press |

Performance and Productivity:

The Dillon RL550C features four stations that handle all critical reloading steps, including:

- Sizing and priming the cases

- Dispensing powder accurately

- Seating and crimping bullets

This streamlined design allows you to produce ammo quickly while maintaining a high level of consistency and quality.

Smart Design and Convenience

One of the standout features is its large capture shotshell storage, which helps keep your shells organized and tidy.

It also includes a primer alert system — if you run out of primers, an alarm triggers immediately, preventing workflow interruptions.

The press is designed to simplify the priming system and other key operations, ensuring a smooth reloading experience for both seasoned and intermediate users.

Precision Powder System

The integrated powder drop measuring system ensures accurate filling for any shell size, helping maintain consistency across every round. This makes it an excellent choice for reloaders who prioritize precision and control.

Durability and Warranty: While the RL550C is on the expensive side, its heavy-duty construction, adaptability, and long-term reliability make it a valuable investment.Plus, Dillon Precision backs it with a great warranty, providing added peace of mind.

Pros and Cons

Pros

- High processing capacity

- Superior shell plate design compared to other models

- Compatible with optional feeders for automation

- Durable and long-lasting build

- Reliable powder drop system

Cons

- Not the most budget-friendly option

- Manual indexing requires user attention

The Dillon Precision 14261 RL550C is perfect for reloaders who want speed, precision, and reliability in one package. Although it comes at a higher price, its quality construction, ease of use, and smart features make it a worthy long-term investment for serious enthusiasts.

4. Lee Precision Load Master 223 Remington Reloading Rifle Kit

If you’re looking for a budget-friendly progressive reloading press that still delivers strong performance, the Lee Precision Load Master 223 Remington Reloading Kit is a solid choice. It’s versatile, efficient, and perfect for reloaders who want both single-stage control and progressive speed — all without breaking the bank.

Key Specifications

| Feature | Details |

|---|---|

| Dimensions | 19 x 11 x 10 inches |

| Weight | 3 kg |

| Brand | Lee Precision |

| Manufacturer | Lee Precision |

| Caliber | .223 Remington |

| Stations | 5 |

| Operation Type | Single-Stage or Progressive (Auto-Indexing) |

Design and Build Quality

This reloading kit features a ¾-inch diameter ram with enough stroke capacity to handle even large magnum rifle cases. Despite being lightweight, it’s sturdy enough to manage consistent reloading sessions.

You can operate it as either:

- A single-stage press for full manual control, or

- An auto-indexing progressive press for faster production.

The five-station setup supports most standard reloading dies, giving you plenty of flexibility.

Ease of Use and Setup

The Lee Load Master comes with a removable turret head that holds your dies securely. You can detach and reattach the turret without losing alignment — a big time-saver for frequent caliber changes.

Setup takes about one hour, but once you’re familiar with the process, you can produce up to 500 rounds per session with ease.

The case loader accommodates multiple case sizes, and the system is quick to adapt to different calibers despite its initial learning curve.

Performance and Value

This model is designed for shooters who want affordability without sacrificing functionality.

It’s a great option if you shoot regularly and want to save on ammo costs by producing your own loads.

The Lee Precision Load Master is one of the most cost-effective progressive presses available, especially for .223 Remington reloaders.

Pros and Cons

Pros

- 5 stations compatible with most common dies

- One of the most affordable progressive presses

- Can handle large magnum rifle cartridges

- Quick and easy caliber adjustments

- Dual-mode operation: single-stage or progressive

Cons

- The powder measure may occasionally require adjustment

- Shell plates and quick-change kits sold separately

The Lee Precision Load Master 223 Reloading Kit offers excellent value for money. It’s a versatile, entry-level progressive press that lets you produce high-quality ammo at an impressive pace.

If you want a reliable press that’s budget-friendly and beginner-accessible, this model is a fantastic starting point.

5. Lee Precision 90940 Lee Precision, Load Master Progressive Press Kit

If you’re looking for an affordable and efficient progressive reloading press that’s great for both rifle and handgun ammo, the Lee Precision 90940 Load Master is a smart pick. It’s flexible, durable, and built to deliver smooth performance for reloaders who value both speed and simplicity.

Key Specifications

| Feature | Details |

|---|---|

| Dimensions | 19 x 11 x 10 inches |

| Weight | 0.57 kg |

| Brand | Lee Precision |

| Manufacturer | Sportsman Supply Inc. |

| Included Components | Progressive Press Kit |

| Caliber Size | .40 S&W |

| Stations | 5 |

| Operation | Single-Stage or Auto-Indexing Progressive |

Build Quality and Design

The Lee 90940 Load Master is constructed from steel and cast aluminum, giving it the strength and durability needed for long-term use. Despite being lightweight, it offers ample space to reload even large magnum rifle cases.

This versatility allows you to use it as either:

- A single-stage press for manual precision, or

- An automated progressive press for faster output.

Flexible and User-Friendly Setup

The press includes five stations that accept the most popular reloading dies.

Its removable turret head makes it easy to swap dies without losing settings — perfect for those who frequently switch calibers.

Changing calibers is quick and straightforward, helping you save time between sessions. Once set up, the press can produce up to 400 rounds efficiently.

Performance and Features

The Lee Load Master simplifies key operations like priming, powder loading, and bullet seating, making the process faster and more convenient.

It’s designed for reloaders who want reliable performance at a budget-friendly price, without needing heavy maintenance.

The included primer feeder functions smoothly, ensuring consistent primer placement throughout your reloading sessions.

Pros and Cons

Pros

- Very easy to set up and operate

- Can load up to 400 rounds per session

- Budget-friendly and upgradeable

- Durable steel and aluminum build

- Reliable primer feeder for consistent performance

Cons

- Instruction manual can be hard to follow for beginners

- Case feeder positioning may require occasional adjustments

The Lee Precision 90940 Load Master is a great choice for reloaders seeking a cost-effective, easy-to-use, and reliable progressive press.

It’s ideal for producing both handgun and rifle ammunition with consistent quality and minimal hassle.

If you want a starter-friendly progressive press that balances performance, durability, and price, the Lee Load Master 90940 deserves a spot on your bench.

Benefits of Having a Progressive Press

A progressive reloading press offers several unique benefits that make it a top choice for shooters, hunters, and competitive reloaders. Here’s what you can expect:

1. Improved Accuracy and Performance

Handloaded ammunition can often be more precise than factory-made rounds.

By controlling every detail — from powder charge to bullet seating — you can produce custom loads that perfectly match your firearm’s performance needs.

This level of accuracy is especially valuable for competitive shooting or precision target practice.

2. Significant Cost Savings

Reloading your own ammunition at home allows you to save money over time.

Buying components like primers, bullets, powder, and casings in bulk is far more affordable than purchasing pre-loaded factory rounds.

With a progressive press, you’ll get more rounds for less money, helping you stretch your shooting budget.

3. Higher Production Volume

A progressive reloading press is built for speed and efficiency.

It enables you to reload a large number of rounds in a short amount of time, ensuring you always have enough ammo on hand.

This means more practice sessions and more opportunities to sharpen your shooting skills without worrying about running out of ammunition.

In short: A progressive reloading press gives you precision, savings, and productivity — the perfect combination for any serious shooter.

How Does a Progressive Press Work?

A progressive reloading press is designed to reload a large volume of ammunition quickly and efficiently, all without needing extra accessories. It’s the ideal choice for shooters who want to produce consistent, high-quality rounds in less time.

Step-by-Step Process

Here’s how a progressive reloading press operates:

- Case Placement

Empty cartridge casings are placed on a rotating shell plate.

This plate automatically advances each casing to the next station with every pull of the handle. - Multi-Stage Operations

At each station, one or more steps of the reloading process are completed, such as:- Resizing the casing

- Inserting the primer

- Dispensing the powder

- Seating the bullet

- No Tool Swapping Needed

Unlike single-stage presses, you don’t have to change dies or tools between steps.

The progressive design handles all processes in one continuous cycle. - Finished Ammunition Output

Once the casing completes all stations, it’s automatically ejected from the shell plate and delivered into a built-in collection bin — ready for use.

Key Advantage

A progressive reloading press saves time and effort by combining multiple operations into one smooth motion. It’s the perfect choice for reloaders who want to maximize output while maintaining accuracy and consistency.

Turret Press vs Progressive Reloading Press: Key Differences Explained

When you’re getting into reloading, choosing between a turret press and a progressive press can make a big difference in speed, efficiency, and learning curve. Both options have their strengths, but if you want to understand which one fits your needs best, let’s break them down.

How a Turret Press Works

A turret press holds just one case at a time in the case holder. The dies rotate on a revolving turret head, performing one step at a time — resizing, priming, powder charging, bullet seating, etc.

Because it handles only one shell per cycle, it’s slower but easier to operate and monitor, making it a great choice for beginners.

Key Limitation:

A turret press can only process one case at a time, which limits the overall production rate.

How a Progressive Press Works

A progressive reloading press is built for speed and automation. Unlike the turret press, it keeps the die head fixed while the case holder rotates, moving several shells through different stations at once.

Each station performs a different task — so with every pull of the handle, multiple operations happen simultaneously.

For example:

- One case gets resized

- Another gets primed

- Another receives powder

- Another gets a bullet seated

This design drastically increases output compared to a turret or single-stage press.

Reloading Rate and Efficiency

The reloading speed depends on the number of stations and additional accessories (like a case feeder).

- Most progressive presses have 3 to 8 stations

- More stations = more operations per cycle

- Average output: 1,000–1,200 rounds per hour

By comparison, a turret press averages 100–200 rounds per hour.

Comparison Table: Turret Press vs Progressive Press

| Feature | Turret Press | Progressive Reloading Press |

|---|---|---|

| Affordability | More budget-friendly | More expensive |

| Shell Handling | One case at a time | Multiple cases at once |

| Die Movement | Dies rotate on a disc; shell stays fixed | Dies stay fixed; base plate rotates |

| Work Efficiency | One operation per handle pull | Multiple operations per handle pull |

| Reloading Speed | ~100–200 rounds per hour | ~1,000–1,200 rounds per hour |

| Ease of Learning | Easier to observe each step | Harder for beginners to track |

| Ideal For | Beginners, small-batch reloaders | Experienced users, high-volume reloaders |

Which One Should You Choose?

- Choose a Turret Press if you’re new to reloading, prefer manual control, or want to learn each step carefully.

- Choose a Progressive Press if you want high-speed production, consistent results, and are comfortable managing multiple processes at once.

Expert Tip

If you’re starting out, it’s often wise to learn on a turret press first to understand each stage of reloading. Once you’re confident, upgrading to a progressive press will help you maximize efficiency and output.

How to Choose the Best Progressive Reloading Press

With so many progressive reloading presses available, it can be challenging to know which one truly fits your needs. To make your decision easier, here’s a breakdown of the key factors to consider when choosing the right press. Once you understand your priorities, comparing different models becomes much simpler.

1. Quality of Material

The durability and longevity of your reloading press largely depend on the materials used in its construction.

- Many progressive reloading presses are made from cast aluminum, which is lightweight and affordable.

- Others are built with solid steel, which tends to offer greater strength and stability.

Keep in mind that cheaper doesn’t always mean weaker. A solid steel press usually provides better friction tolerance and long-term reliability.

Before purchasing, always inspect the small moving parts for any signs of weakness, as these can sometimes develop cracks or distort over time.

2. Ammo Type Compatibility

Different reloading presses are designed for specific ammunition types.

- Some models are ideal for rifle ammo,

- Others are made for pistol or small-caliber shells.

Certain presses support only one caliber out of the box, but you can expand their capabilities by adding conversion kits. Just remember — while these kits increase versatility, they also add to the overall cost.

If you often reload multiple calibers, investing in a versatile press will save you time and effort in the long run.

3. Reloading Speed

Your reloading goals should guide your press selection.

Ask yourself:

- Do you want to reload slowly for maximum precision?

- Or do you need to produce high volumes of ammo quickly?

On average, progressive reloading presses can produce 400–800 rounds per hour, depending on the model.

In general, higher-end presses offer faster and more consistent results, making them worth the investment for serious reloaders.

4. Finished Round Production

Reloading involves multiple steps — resizing, priming, powder charging, seating, and crimping. The efficiency of these steps affects your output speed.

Look for presses with:

- Auto-indexing systems — these automatically rotate the shell plate with each handle pull, ensuring smooth and fast operation.

- Powder measuring accuracy — advanced models calculate the exact powder load for consistent performance.

If you reload several calibers regularly, a progressive press with automatic indexing and easy adjustment is your best choice.

5. Assembly and Ease of Use

Progressive presses can produce large quantities of ammunition quickly — but they often require more setup time than single-stage or turret presses.

They’re heavier and can be complex to assemble, especially for beginners.

If you’re just starting out, choose a model with:

- Simple setup instructions

- Pre-assembled features that reduce installation time

A user-friendly design will make your learning experience much smoother.

6. Additional Accessories

Many manufacturers offer optional accessories that enhance your reloading experience.

Examples include:

- Case feeders for automatic shell loading

- Bullet feeders for hands-free operation

- Powder dispensers for accurate measurements

These extras can save you significant time, so consider a model that supports upgradable attachments or includes them in a complete reloading kit.

7. Affordability and Value

Your budget will play a major role in your choice.

If you’re ready to invest in a high-end press, you’ll enjoy faster production and advanced features.

But even with a smaller budget, you can still find reliable, durable options.

Focus on:

- Build quality

- Reloading speed

- Expandability

With a bit of research, you’ll find the best progressive reloading press that fits both your needs and budget.

Choosing the right progressive reloading press comes down to balancing quality, speed, versatility, and price.

Take time to identify your reloading goals and the type of ammunition you’ll work with most often.

Once you know what matters most, you’ll be able to invest in a press that delivers precision, consistency, and long-term value.

Best Progressive Reloading Press by Editors’ Choice

Hornady Lock-N-Load AP Press Loader

If you’re looking for a top-tier progressive reloading press, the Hornady Lock-N-Load AP Press Loader is one of the finest options available today. It’s built to deliver speed, precision, and long-lasting performance — everything a dedicated shooter or hunter could ask for.

Key Specifications

| Feature | Details |

|---|---|

| Dimensions | 20 x 14 x 11 inches |

| Weight | 29 pounds |

| Brand | Hornady |

| Material | Cast Iron |

| Warranty | Lifetime Warranty |

| Reloading Capacity | Up to 500 rounds per hour |

Outstanding Build Quality and Performance

Constructed from durable cast iron, the Hornady Lock-N-Load AP Press is designed for heavy-duty performance and long-term reliability. Each pull of the lever performs multiple operations simultaneously, allowing you to produce up to 500 rounds per hour with consistent accuracy.

Whether you’re crafting traditional-style bullets or modern high-performance ammo, this press offers the strength, stability, and versatility to handle it all.

User-Friendly Progressive Design

This press features five stations with quick and easy caliber changes, ensuring smooth workflow and minimal downtime. Its Lock-N-Load bushing system makes die changes incredibly simple — just twist and lock.

You’ll also appreciate the quick-change plate system, which makes bench installation fast and secure.

Auto-Indexing for Fast, Accurate Reloading

One of the standout features of the Hornady AP Press is its auto-progressive reloading system. The auto-indexing function ensures precise case alignment and movement through each stage, significantly speeding up the process while maintaining top-level accuracy.

Switching between calibers, such as .223 to .45, takes less than five minutes, giving you maximum flexibility for various ammunition types.

Precision Customization

The included scale and components allow you to fine-tune and create customized loads based on your shooting preferences. This makes it a perfect choice for reloaders who value control, consistency, and precision.

Why Choose the Hornady Lock-N-Load AP Press?

- High production speed – Up to 500 rounds/hour

- Easy caliber switching – from .223 to .45 in minutes

- Durable cast iron construction

- Auto-indexing and progressive operation

- Lifetime warranty for peace of mind

If you’re serious about efficient, high-volume reloading, the Hornady Lock-N-Load AP delivers professional-grade performance in a user-friendly package.

Frequently Asked Questions (FAQs)

1. What is the main advantage of a progressive reloading press?

A progressive reloading press lets you perform multiple steps — like resizing, priming, powder charging, and bullet seating — at the same time. This saves time and allows you to produce hundreds of rounds per hour, making it ideal for shooters who need speed and efficiency.

2. Is a progressive reloading press good for beginners?

It depends on your experience. Progressive presses can feel complicated at first because they perform several tasks simultaneously. But beginner-friendly models like Lee Precision 90940 Load Master or Lee Load Master 223 come with simple setups, making them suitable even for new reloaders.

3. Which is better: turret press or progressive press?

If you value speed and volume, the progressive press is better — it can load 400–800 rounds per hour.

If you want to learn each step carefully and prefer more control, a turret press is easier for beginners and safer for learning.

4. How many rounds can I produce per hour with a progressive press?

Most progressive reloading presses can produce between 400 to 800 rounds per hour, depending on the model and operator’s experience. High-end options like the Hornady Lock-N-Load AP Press can even reach 500+ rounds per hour with consistent performance.

5. What accessories improve the performance of a progressive reloading press?

Accessories like a case feeder, bullet feeder, primer alert system, and powder measure help increase productivity. These tools make the press more efficient, reduce manual steps, and ensure consistent results.

6. Are progressive presses worth the money?

Yes, for regular shooters and hobbyists, a progressive reloading press is a smart long-term investment. It saves time, reduces ammunition cost, and gives you precise, consistent rounds — which is especially useful for competitive or frequent shooting.

Final Verdict

Choosing the best progressive reloading press depends on your needs and experience.

If you want speed and precision, the Hornady Lock-N-Load AP Press is a top performer.

For budget-friendly and beginner-friendly options, the Lee Load Master 223 or Lee 90940 are excellent picks.

Each model delivers reliable performance, saves time, and ensures consistent, accurate ammo for years to come.