Single stage reloading presses are great for a variety of users. This reloading press comes for budget-conscious people, special for those who want a basic result with a lot of versatility, and even competitive shooters who need the most precision possible. These are ideal for both novice and specialist reloaders who want flawless ammo.

This kind of press is a great starting point if you’re looking for something basic to use with a pistol or shotgun. This press is also able to provide the most precision possible. These reloading presses are the steadiest and most basic reloaders. These are capable of transforming the workbench into a skilled reloading station.

Related Post:

If you’re just getting started, don’t expect to load thousands of rounds all at once. And if you also want to start reloading, you’ll need the best single stage reloading press for accuracy. It integrates the elements of ammo into a firing cartridge. We did extensive research to help you find your preferred single stage press.

Best Single Stage Reloading Press

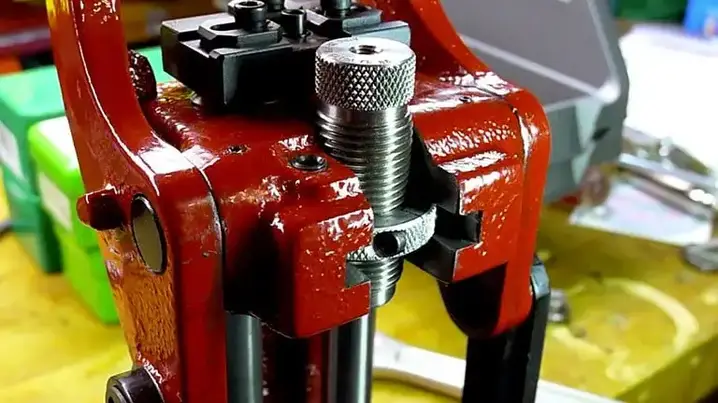

1. RCBS 9356 Rock Chucker Supreme Press

Specifications:

- Dimensions: 20 x 15 inches

- Weight: 19.8 Pounds

- Brand Name: RCBS

- Warranty: Lifetime

Due to the ambidextrous structure, switching between your hands during a long reloading session is simple. The O-frame provides lots of working space. This RCBS Rock Chucker Supreme O-frame press allows rifle cases to fit easily.

Long reloading operations are made easier with the ball adjustable handle. It is simple and convenient to use. The entire system runs smoothly and quickly.

This reloading press is strong and substantial. RCBS Rock Chucker Supreme is mainly designed to handle heavy-duty reloading, case shaping easily, and bullet swagging. It can withstand whatever load you put on it and is also adaptable.

If you require additional productivity, their Piggyback-4 modification kit can turn this press into a high-capacity loader. The Piggyback-4 converts this press into a 5-station RCBS progressive press with manual indexing. To further improve the equipment, you can add a star wheel to this improvement.

The versatility of this press is incredible. If you have the room and the courage, you may make this basic press RCBS bigger and more intricate.

PROS:

- Extremely well built

- It can be used by both hands

- Heavy duty

- Contains O frame press

- A ram of one-inch diameter is simple to operate

- Made from cast iron

CONS:

- Quick and sub-par die-changing system

- Heavy

2. LEE PRECISION Anniversary Challenger Kit II

Specifications:

- Brand Name: LEE PRECISION

- Manufacturer: LEE PRECISION

- Part Number: NA

- Size: 1 Unit

This reloading press is also one of the most famous reloading presses on the market, not only because it’s cheap, but it’s also quite adaptable.

Since it may be used for decapping, sizing, seating, as well as crimping. You get a pretty heavy-duty design with the famed “O” shape for the frame and the cast iron construction.

The opening window is 4.25 inches wide, giving you more room to work with and allowing you to see more precisely. The entrance is even angled at a 30-degree inclination for better vision and maneuverability.

The Breech Lock quick-change die mechanism is fantastic. This is because it makes swapping dies so simple. This task only involves a twist of the wrist, with no need to reposition the dies. Priming becomes a lot easier now that you have both big and tiny priming arms. The design even allows you to drop used primers directly into the garbage can, saving you time and energy. You’ll be able to alter the length to make working with it simpler.

It also works for those who are left-handed. This may be used to reload 223 and other calibers on a single-stage press, as well as 273 and 30.06. It’s just not designed for the massive 0.50 BMG. We can easily conclude that this is the best single-stage reloading press kit.

PROS:

- You can get a full set at a reasonable price

- Almost all sorts of longer cartridges can be reloaded.

- Easy to set up

- Digital powder scale sizing in almost every dimension

- Has chemical compound leverage

- The classic package for setting instances includes a hand priming tool.

- The media’s frame press layout has a lot of space.

- Quick Change Breech Lock

- The guidebook is simple to read

CONS:

- The shell holders must be purchased separately.

- The powder scale may have a delay in calculating the weight.

3. Frankford Arsenal M-Press Coaxial Reloading Press

Specifications:

- Dimensions: 1 x 1 x 1 inches

- Weight: 21 Pounds

- Brand: Frankford Arsenal

- Warranty: 1 Year

This single stage reloading press is designed with an easy-to-empty spent primer. With the flip of a dial, you can switch from a little pistol to magnum pistol or gun-sized instances.

The floating die technology ensures bullet as well as case alignment. This reduces the runout and allows for the most exact ammunition possible.

Frankford Arsenal’s unique M Press gives unrivaled accuracy both on the field and on the bench. The universal shell holder plate design is a defining quality. This design includes two round disks that spin and an “indicator” at 90-degree spacing beneath a metallic plate. Cutouts for small, large, 223, and 308 instance rims are incorporated on these disks. This press can use any reloadable cartridge, even the 338 Lapua!

After loading, you designate a position on the base plate. The shell-holding plates move towards the position by lifting the ambidextrous handle. After you clamp it in a fixed location, it is ready for the case or cartridge to be primed and inserted into the die-changing mechanism.

PROS:

- Contains ambidextrous handle

- The integral “floating” shell-holders plate design is simple to change.

- It has a quick-change die system

- Easy to reload

- Holder stays in place

CONS:

- Sometimes, dies do not align with the case holder.

4. RCBS Summit Single Stage Reloading Press

Specifications:

- Dimensions: 18 x 8 x 6 inches

- Weight: 9 Pounds

- Brand: RCBS

- Model: 09290

Single stage reloading presses are often designed in such a way that they enable using your reloading press to be pleasant and simple. Reloading will be as much pleasure as shooting with this stylish reloading press from RCBS.

Customers have given 5-star reviews to the RCBS Summit, which is made of DAPPER components. RCBS is a reliable brand to consider if you’re looking for the best single stage reloading press.

Brooding the case in its place produces improved outcomes since it produces more modern ammunition than those that go up to the die station. This ensures that only the dies move on the reloading press while the brass remains firm, giving you complete accuracy.

While reloading the brass, RCBS assures that you are at peace. You may experience the highest comfort as well as top-quality bullets if you use this amazing single stage reloading press. You may utilize the reloader on either the right or left side, depending on whether you are a right or left-handed user.

The ram of a reloading press is a crucial component. The greater the width, the better. The ram of your press will support the maximum weight and technique of reloading your ammo. The 2″ ram diameter simplifies things even more.

Moreover, the spent primer tray is positioned directly beneath the shell holder, collecting all used primers. After a long period of reloading, your displeasure with cleaning it up lessens.

The RCBS Summit also has a vast opening frame that is around 4.5 inches in length. It allows you to resize your bullets on various types of brass and make them live longer than your standard ammunition. If you work on this masterpiece, sizing the longest brass will not be a problem.

PROS:

- It retains the brass in place and does not shake or dislodge it.

- Able to work with a variety of dies and ammunition

- Easy-to-use

- It takes only a few minutes to set up.

CONS:

- On a smaller bullet, the shorter handle works nicely.

5. Forster CO-AX Single Stage Reloading Press

Specifications:

- Dimensions: NA

- Weight: NA

- Brand Name: Forster

- Warranty: NA

The Forster Co-Ax single stage reloading press, as its name indicates, it is a co-axial frame reloading press. This transmits the highest load with low-pressure thanks to its co-axial frame construction. Forster states that you can use the press with your little finger since charging the handle is so simple.

On the Forster Co-Ax, a standard dies to screw on firmly at the head of the press. It also has an ambidextrous handle situated in the core of the press.

Rather than shell holders, the Forster Co-Ax single stage reloading press employs a unique shell holder mechanism termed Jaws, which employs a changeable spring-loaded jaw. The Jaws open and shut on the case, assuring that the case and die are perfectly aligned. To seat and crimp the bullet, this alignment is crucial. This Jaw system not only saves your expense by eliminating the need for shell holders, but it also makes reloading much simpler.

When you alter the caliber you’re reloading, you don’t have to worry about mounting and replacing a shell holder. The “S” jaw features on the Forster Co-Ax press for most calibers, but “LS” jaws are available for less popular calibers such as 218 Bee, 22 Hornet, and 25 ACP.

PROS:

- Accurate and simple

- Ram stroke is seamless and precise.

- Perfect priming on the press

- Directions are simple to understand.

- High quality

CONS:

- The Bullet area is smaller.

- It’s a little pricey.

6. Lyman 7726500 Brass Smith

Specifications:

- Dimensions: 16 x 18 x 14 inches

- Weight: 1 Pound

- Brand: Lyman

- Warranty: 1-year manufacturer

Lyman is praised for offering a well-designed single stage reloading press with high-quality parts. The Lyman Brass Smith Ideal Press is a great pick for a single stage press since it is one of the simplest to operate, most basic configurations, and most inexpensive presses available.

Its motion is swift and simple, moving through all the phases of the reloading process fast. This makes it not only a productive but also a pleasant activity. This reloading press is excellent for newbies because of its endurance and surprisingly low price.

This Reloading press has on-press mounting with various primer assistance and a convenient lever to prim the brass. You can reconfigure, de-prime, and prime with only one up-and-down rotation of the handle. Disconnect the primed brass case, replace it with a new one, and repeat the process.

It’s easier than other methods where you need to add primers individually. The long ambidextrous handle gives you plenty of leverage for reloading rifle cases and military ammunition. One advantage is that the shell holder can be accessed from the side, allowing for easy case removal and installation.

Overall, the press’s C frame construction provides for simple access throughout the operation. When reloading, visibility is equally excellent. When reloading, cast iron, not aluminum, provides a firm feel, and the handle location is highly user-friendly.

PROS:

- Affordable

- It has an ambidextrous holder

- Easy to use

- Simple configuration

- Excellent for beginners

- The shell holder and die align

CONS:

- Not as smooth as others

- Ram is rough

- Pivot is sloppy

7. LEE PRECISION 90685 Cast Iron Reloading Hand Press

Specifications:

- Dimensions: 13 x 4 x 2 inches

- Weight: 0.42 Kilograms

- Brand: LEE PRECISION

- Color: Red

LEE PRECISION 90685 Cast Iron is a lightweight single stage reloading press, which is also easy to operate. It is made of aluminum and is quite durable. Because the press only weighs 1-12 lbs, you can simply place it on a Reloading bench or reloading table, anywhere you like.

This machinery does not require any sophisticated mounting tools. Changing dies isn’t an issue because the breech lock mechanism is also compatible.

It works with dies ranging in size from 7″ to 14″ and takes die bushing. The nicest part about this equipment, and the reason we rated it as the finest single stage reloading press, is that you can easily de-cap and size during extended reloading periods.

PROS:

- Easy and straightforward to use

- Very practical and basic

- Cheap

- Sturdy

- Saves space

CONS:

- Consumers power

- Slow processing

- Not designed considering comfort.

What is Singal Stage Reloading Press?

The single stage reloading press is the simplest basic sort of press. This reloading press can only handle one die at once, has an extremely stiff frame, and is most usually utilized for refilling rifles. A shell holder is linked to the ram. This retains the cartridge case rim, and the dies are inserted into a hole at the upper edge of the press. The ram rises when the lever is pressed downward, and the die works on the case. Priming is typically accomplished by hand priming setup.

However, some single stage presses include priming accessories. Single stage presses are the slowest and steadiest to finish rounds each hour.

Why Singal Stage Reloading Press?

The single stage press provides plenty of advantages while using it. Some are listed below:

Reduces the expense

If you fire a lot, you’ve probably realized that shooting all those rounds of ammo costs a lot of money. This is particularly evident if you continue to purchase factory-made ammunition.

However, reloading your ammunition with a reloading press may save you a great deal of money. Some shooters discover that they may reduce their ammunition costs by as much as 50 percent.

Of course, you may spend the same sum of money on ammunition, but you will have approximately twice the amount of ammunition. That’s much more enjoyable, and the money is well-used.

Better comprehension

A reloading press allows you to complete tasks one at a time. That isn’t necessarily a negative feature. If you are a beginner at reloading, you’ll know better how it all operates concerning your ammunition. It aids in your overall understanding of shooting.

Even skilled reloading shooters occasionally utilize their single stage reloading press. They may concentrate more on each step of the procedure, reducing mistakes and allowing you to produce more accurate ammunition. It is even soothing to do. Compared to using a huge fishing boat to bring in more fish, utilizing a single stage reloading press is like a fishing solo.

How to Reload Ammo with Singla Stage Reloading Press?

Let’s assume you want 100 reloaded rounds in the end. If you’ve perfected the overall procedure and are doing things almost effortlessly, you can accomplish it in an hour using a single-stage reloader.

- Begin by filling your reloading press with the sizing or de-priming die.

- Pull the lever to make sure it’s operating correctly.

- After that, you can insert a piece of brass into the press.

- You resize and de-prime the cycle every time you pull on the lever. That is, the old primer is punched out, and the brass is the proper size for reloading.

- Carry on like this for the rest of your rounds, until each one has been shrunk and de-primed.

- You’ll need to manually charge each piece of brass with powder employing a little dipper at this stage.

- After you have charged all of the brass parts, you may insert a bullet seating die into the press.

- Then, individually, you may seat all of your bullets into every cycle.

- After that, apply the reloading press to crimp each of the 100 rounds one after the other.

- You’ll have 100 reloaded rounds in the end.

Single Stage Vs Turret Press

The single stage reloading press is similar to the turret press in several aspects.

Working with a single case at a time is possible with the turret press just like the single-stage press. In truth, the sort of shell holder is similar in both models.

It’s only that with the turret press, you have a disk that can carry many dies at the same time. You could discover three to seven dies. Rather than replacing the die and inserting a new one, like with a single-stage reloading press, you can just spin that disc for it works. As a result, the turret press makes things a lot simpler and quicker. Some of these turret presses include automated indexing. This means that as you lift the press handle, the turret spins to switch to a fresh die.

However, because it is significantly cheaper, the single-stage can still appear alright for most individuals. It’s also easier, so newcomers won’t be intimidated by a more difficult procedure. Furthermore, more complex systems mean that more things may go wrong.

Single Stage vs Progressive Reloading Press

It’s true that the majority of folks who continue to reload ammunition end up owning a progressive reloading press. This is due to the progressive press’s high efficiency. You can only do one activity at a time using the single-stage, and you can only use one dice each time.

However, with a progressive reloading press, you can now do many operations with each pull of the handle. Each movement of the press arm can result in a completed round every time. You can obtain about 100 rounds per hour with the single-stage. You can go up to 400 or even 500 cycles per hour with a progressive.

Excessive reloading on a single-stage press isn’t the greatest solution in this case. The problem is that a progressive reloading press is significantly more costly and complex. It’s not for beginners, but it’s ideal for individuals who want to get things done quickly.

Things to Consider Before Buy a Single Stage Reloading Press

While most single-stage reloading machines operate similarly, they are not identical. Some models may have additional characteristics or functionalities.

Emphasize the following criteria while reading single stage reloading press evaluations:

Materials

When it comes to selecting your single-stage reloading press, the structural material should be considered. The majority of other single-stage presses are made of cast iron, which is a very sturdy material. If you’re looking for more mobile reloading equipment, you can choose a lighter-weight material. A single-stage press made of aluminum or a resilient polymer may be more appropriate in this case.

Affordability

Because you must consider the value of the single-stage reloading press into your budget, any sensible customer must consider the pricing. Certain models are more costly than others. However, they may have additional features and benefits not seen in the less expensive versions. You don’t need a reloading press that operates with extended cartridges if all you want is a pistol reloading single-stage press. You’ll save money this way.

Priming

Because not all single-stage presses include priming choices, you’ll need to use a hand priming tool to finish the task. Even though some have the potential, you will need to acquire another piece of machinery. It is preferable to have that equipment with the primer arm attached at all times when priming is required. You can also think about getting an automated primer arm.

Complete reloading presses or stand-alone reloading presses

Many beginners find that purchasing a whole kit is far more efficient. That means you’ll receive the single-stage reloading press as well as all of the necessary attachments. So you can get started right away. This saves a great deal of time because you won’t have to go out and get the rest of the items you’ll need. You may also rest certain that all of the included accessories are compatible with the reloading press. One of the issues with purchasing reloading press components is that you may realize later that the component you purchased does not function with your reloading press. It’s also possible that purchasing a whole kit will result in a discount. If you purchased all of the kit’s materials individually, the overall cost would be significantly greater. The biggest disadvantage of a kit is that the components may or may not be as excellent as the reloading press. The single-stage reloading press may be superb, but the components may be lacking. You can end up having to spend on accessories that you’ll eventually need to replace.

Brand

You may have observed that all of the single-stage reloading presses on our list are from well-known manufacturers. There is no such thing as a Johnnie-come-lately brand here. This is because these manufacturers have a track record of producing high-quality reloading presses. Because of their past record, you have a better chance of acquiring a high-quality product for a greater cost.

If you’re looking for a respected brand for your reloading presses, go no farther than RCBS, or Lee Precision according to our preferences.

RBCS: This company has been in the reloading business for more than 60 years and has earned a reputation for trustworthiness. The ATK Civil Ammunition Systems Group owns and operates RCBS. Because this collection of firms specializes in military armament, you may be confident in the RCBS goods you get. With the RCBS reloading tool line, you can even stick to one manufacturer and obtain everything you require.

Lee Precision: Lee Precision’s actual tale begins with the development of the now-iconic Lee Loader for shotgun ammunition. This instrument was invented by Richard Lee at his residential workshop in 1958. He came up with the Lee Loader for rifle ammo and the Lee Loader for handgun ammo in the early 1960s. These loaders collectively serviced up to 1.5 million shooters in the United States. With various inventive equipment and models throughout the years, Lee Precision has developed a pioneering name. Their items come with substantial warranties, including unconditional 2-year warranties and limited lifetime warranties.

Durability

You can save money by reloading your ammunition. But if you continue purchasing cheap reloading presses that don’t operate longer, that won’t be the situation. This is one of the causes why we only buy reloading presses from well-known companies since these firms have a confirmed past reputation for producing long-lasting products. They’re also noted for sticking to their warranties. For the reloading press, seek a strong frame that will offer the mechanical stability you require. Your reloading press should be built of steel or cast iron.

Ease of use

The frame should also provide your hand with adequate room to work more effortlessly and rapidly. Check for elements that make the reloading press steady as well. Because you’ll be replacing dies frequently, you’ll want to choose a solution that allows you to do so quickly. As a result, you won’t have to make many modifications throughout the reloading process. The simpler it is to use, the more rounds you can reload in a given amount of time. It’s less challenging for rookie shooters and more soothing for professionals.

Handle quality

One of the items you’ll utilize the most is the handle. It must be convenient for you to utilize. Some individuals like a smooth ball grip on the handle since it reduces hand cramping over time when you move on the lever dozens of times. It should be ambidextrous as well, particularly if you’re left-handed. It irritates the southpaws when the handle is solely designed for right-handed reloaders.

Best Single Stage Stage Reloading Press By Editors’ Choice

Lee Precision Cast Iron Hand Press is the most popular single-stage reloading press. We must first analyze the brand, as we are already aware that this name is associated with high-end single-stage or turret presses. Novices are always encouraged to use this item since everything works, from the very precise powder measure to the easy shell holders. This is a typical reloading kit that is beneficial to both amateurs and experienced reloaders. This single-stage reloader is user-friendly, practical, and quite beneficial.

FAQs

Who Makes the Best Single Stage Reloading Press?

Lee Precision is a great brand to support and mimic regarding reloading presses. Many other companies mimic the unique characteristics of Lee Precision presses and die, and the company has a large following. This brand is unique because many other replicas are only marginally better than Lee Precision’s machinery, although Lee Precision’s presses and other instruments are still cheaper overall.

Is Single Stage Reloading Press Upgradable?

A competent single-stage reloading press will satisfy many shooters who are recent to reloading. However, many of them eventually want a more effective reloading press to reload more rounds of ammunition faster. This necessitates the use of a progressive reloading press. For more productive reloading, you can simply purchase a new progressive reloading press. You can still use the single-stage reloading press on occasion because many shooters find it calming. However, you might want to seek a single-stage device that you can convert to become a progressive reloading press. In the long term, this helps you save money.

How to Set Up a Single Stage Reloading Press?

Most of the single stage reloading press comes pre-assembled and needs little to no setup. The manual provided by the brand is easy-to-understand for setup. Following it can do the trick.

Will Lyman Reloading Dies Fit the Lee Single Stage Press?

RCBS, Lee, Hornady, Dillon, Redding, and other prominent presses that use industry-standard 7/8″ x 14 threads can use Lyman dies.

How to Mount Lee Single Stage Press?

Hold the press properly so that it does not fall off the edge. First, you need to drill the first hole and leave the press in place. Then, drill the other two holes so that you have nice straight holes in the table and the bolts slip through easily. Make sure the edge of the bolt will be right at the joint between the trim and the plywood if you need to trim. After you are done drilling, attach the press to the table using bolts. Use two flat washers and a lock washer for each one. The two washers will help it stay stiff as you tighten it. Without the washers, the nut can get sucked into the wood and loosen over time.

Final verdict

One of the first things you should do before starting to reload your ammo is to invest in a single-stage reloading press. Begin by determining your budget and then searching for a single-stage reloading press within that range. Any of the presses from this list will not disappoint you. All of them can reload high-quality ammo for your pistol or rifle for a reasonable price.